Automated Assembly

According to the different characteristics of products, we have divided our assembly production line into two: automated assembly line and manual assembly line. Our professional engineers not only can design the labor power into the automated assembly system, but also are able to develop and improve the automated assembly machines, as well as defective product detecting system. Hence, we can ensure the quality of product also improve the productivity. Recent years, in order to reduce the production costs and improve market competitiveness, we have reduced the cost in manual production and focused on the development of automation equipment, to ensure product quality and production capacity. Production efficiency will lead the delivery time become more accurate.

Innovation & R&D

We have a group of experienced R & D team and professional engineers. They can design, manufacture all kinds of plastic, metal mold and equipment. Hence Cabcon can provide the customer full set of product development, manufacturing and processing technology. Our professional design and efficient R & D team can proceed accurate and fast development to meet customers requirement.

We have several components you will find useful in fully automatic production. We believe that we must think smarter in the design phase, and we strongly believe we can help to choose the right components, so your production can run in only one process. We are always considering and discussing design for manufacturing on new products.

Rules & Regulations

The commitment of continuously improving to meet the sustainable development. Not only the production of high-quality products, but also practice and follow the rules of environmental protection. Cabcon Contact is dedicated to protecting our working and living environment. Every production process must have an impact on the environment, and we greatly reduce the damage to the environment; hence we have implemented environmental policy and to view the environmental protection as our main goal.

Complies with all relevant environmental protection laws, regulations and guidelines.

Use the minimal natural resources and maintain the balance of ecological system.

To avoid any damages (such as collect raw materials, production and disposal) to the environment.

Reduce the waste materials of production, use of recyclable materials.

Improvement of waste disposal methods in production.

Improve the company’s internal and external environmental protection knowledge and communication.

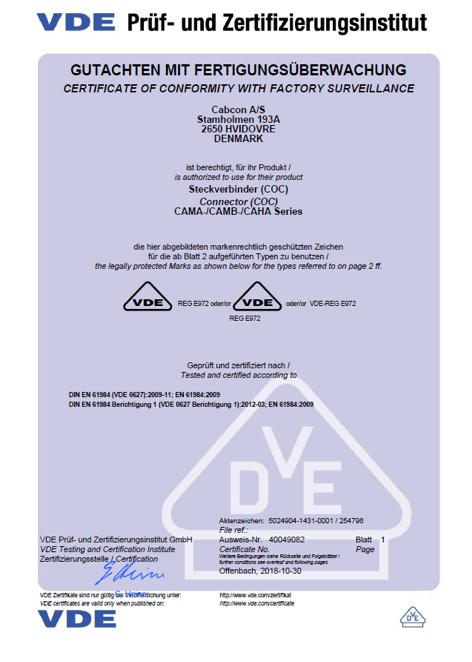

Standards & Approvals

According to international requirements, most of our products are and will be designed to meet UL and VDE regulations. Authorizations are an important factor. We provide terminal blocks and multi-connector systems in accordance with current applicable standards and regulations. We meet EN 61984:2009, EN 60998-1:2004, EN60998-2-1:2004 , EN60998-2-2:2004 ,EN60947-1:2007+A1:201+A2:2014 , EN60947-7-4:2013 for Terminal Blocks both the plug-in terminals with screw and the screwless terminals. Our multi-connector systems are approved according to EN61984. Our cULus terminal block and multi-connector system approvals are based on the UL1059 and CSA22.2 No.158 standards.

Quality

Quality assurance is a prerequisite for Cabcon A/S continued development and is essential for customers choosing Cabcon A/S a supplier. We ensure that quality is an integral part of all the company’s departments. To comply with quality standards. The management of quality issues based on the principle of “zero” error in each step of our process. That employees continuously work with quality issues and active and responsible participant in the work to achieve expected quality. The quality requirements for products and services, the Group is purchasing, or delegate to subcontractors, corresponding to the demands we place on ourselves. The suppliers’ quality work is assessed. We set clear quality requirements and evaluate regularly how the supplier meets the requirements.

We always have said “quality comes first”. We strictly implement the ISO9001 quality assurance system form day 1. From the purchase of raw materials to manufacturing, product delivery, each process all has strictly goods inspection and quality control. To ensure the traceability and integrity of information, the data acquisition efficiency, accuracy and data acquisition feasibility, all the data collection will use bar code technology and rational distribution of acquisition to complete traceability information acquisition.